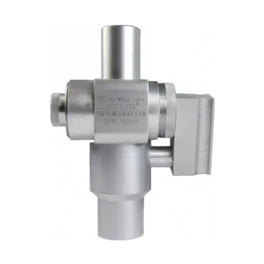

BGI SCC 2.229: PM1 Sharp Cut Cyclone

Turn Your FRM Sampler into a Precision PM1 Monitor—Instantly

The SCC 2.229 Sharp Cut Cyclone is the industry-standard inertial separator designed to isolate sub-micron particulate matter (PM1) with exceptional aerodynamic precision. Manufactured by BGI (Mesa Labs), this cyclone is engineered to operate at the regulatory flow rate of 16.67 LPM (1 m³/hr).1

Its primary design advantage is its form factor: the SCC 2.229 is a direct mechanical replacement for the WINS impactor.2 This allows operators to convert any US EPA Federal Reference Method (FRM) PM2.5 sampler into a high-precision PM1 research sampler in seconds, without the need for tools, adapters, or complex recalibration. It provides a robust solution for researchers and air quality networks aiming to study the "sub-micron" fraction—particles most associated with combustion sources and deep lung penetration—using their existing hardware infrastructure.

Key Benefits

Tool-Free WINS Replacement: The cyclone features the exact "socket and tenon" dimensions of the standard WINS impactor. You can simply unplug the WINS well from your FRM sampler (e.g., PQ200, Partisol) and plug in the SCC 2.229 to switch from PM2.5 to PM1 monitoring immediately.

Dry Separation System: Unlike impactors that require oiled substrates and frequent re-greasing to prevent particle bounce, the SCC 2.229 uses dry cyclonic flow. This eliminates the risk of oil contamination on your chemical speciation filters and significantly reduces maintenance labor.

Extended Sampling Intervals: The high-efficiency design resists clogging even in moderate loading conditions. While WINS impactors often require cleaning every 3–5 days, the SCC 2.229 can typically operate for up to 3 weeks (depending on local pollution levels) without performance degradation.

Defensible Data Quality: The "Sharp Cut" designation refers to its steep efficiency curve, ensuring a precise cut-point at 1.0 µm. This minimizes the intrusion of larger coarse mode particles, ensuring your chemical analysis reflects true sub-micron aerosols.

Technical Overview

The SCC 2.229 utilizes tangential inlet geometry to create a stable vortex at 16.67 LPM. As the air stream spins, particles larger than 1.0 µm are forced to the outer walls by inertial, centrifugal forces and drop into the grit pot. Only the ultra-fine PM1 fraction follows the airstream up through the immersion tube to the 47mm filter cassette.3

Compatibility Note:

This cyclone is designed for "Type 3" sampling configurations and is compatible with practically any ambient air sampler configured for 16.67 LPM flow with standard EPA inlet dimensions.4 It is widely used for chemical speciation sampling because it does not use impaction grease, which can interfere with organic carbon (OC/EC) or semi-volatile analysis.

Typical Use Cases

Combustion Source Apportionment: Isolating PM1 allows researchers to focus on exhaust emissions (diesel/traffic) and wood smoke, filtering out mechanically generated dust (which is usually larger than 1 µm).

Indoor Air Quality (IAQ) Studies: Monitoring penetration of outdoor pollutants into buildings or assessing HVAC filtration efficiency for sub-micron viruses and aerosols.5

Epidemiological Research: Assessing the health impacts of the smallest, most penetrating particle fractions that enter the bloodstream.

Background Station Monitoring: Used in pristine environments where PM2.5 and PM10 levels are low, and the majority of aerosol mass is in the sub-micron range.

Why Choose This Cyclone?

The SCC 2.229 is the standard-bearer for PM1 research. It saves agencies thousands of dollars by repurposing existing PM2.5 inventory for emerging PM1 studies. Whether you are conducting short-term "saturation studies" or long-term background monitoring, this cyclone offers the reliability of a dry system with the geometric precision required for peer-reviewed publication. It removes the "grease and labor" headache of impactors while sharpening your data's focus on the most hazardous particle fraction.

Specifications

Measured Components:

PM1 (Particulate Matter ≤ 1.0 µm aerodynamic diameter).

Applications:

Ambient air research, Chemical speciation (OC/EC), Indoor Air Quality (IAQ), Epidemiology, Conversion of FRM samplers.6

Certifications:

Designed to US EPA aerodynamic specifications for Sharp Cut Cyclones; Verified in peer-reviewed literature (Kenny et al., Gussman et al.).

Measurement Principle:

Inertial Cyclonic Separation (Dry).

Flow Rate: 16.67 LPM (1 m³/hr).7

Cut-Point (D50): 1.0 µm.

| Applications | CEMS (Continuous Emissions Monitoring Systems), Environmental Protection, Industrial Emissions, Marine Diesel Engines, Ambient air quality, Stack Gas Analysis, Fence Line Monitoring |

| Brand | BGI/Mesalabs |

| Measured Components | PM1 – Particulate Matter ≤ 1 µm |

| Measurement Principle | Inertial Cyclonic Separation |

| Certifications | US EPA Class III PM2.5 Federal Equivalent Method |